- Induction Heating Rolle

- Flexible copper clad la

- Mirror Roller

- Comma Scraper

- Coating Roller

- Heating Roller

- Chilling Roller

- Stainless Steel Roller

- Guide Roller

- Calender and Casting R

- Rubber Roller Series

- Anilox Roller

- Extinction Roller

- Telfon Roller

- Other Roller

PRODUCTS |

YOUR CURRENT LOCATION:HOME > PRODUCTS |

Materials : High grade 45#steel, alloy steel, precision steel.

Processing:heat treating ,destressing,finish turning,quenching.

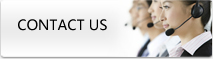

Inner structure:

The structure from inside to outside : center shaft, insulation layer, heating layer, radiation layer, heat preservation layer,

reflecting layer and high temperature coating layer.

Heating method:

Electromagnetic induction heating .( energy-saving efficiency: 50%-70%. The maximum temperature of the roller surface can reach above 400℃).

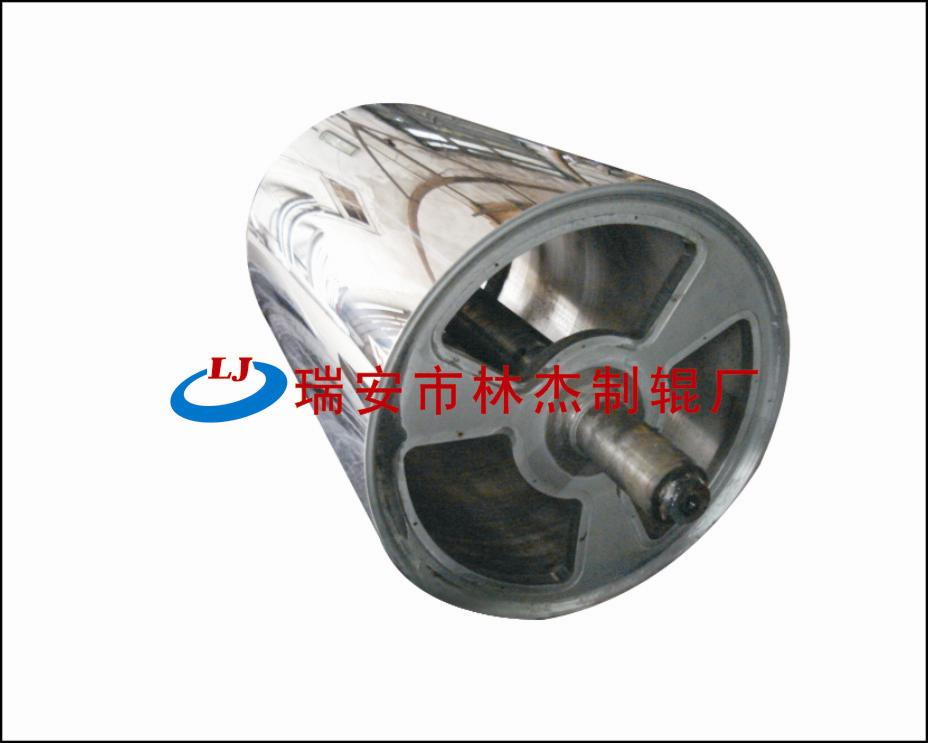

Surface treatment

hard chrome plating,spraying ceramic or tungsten carbide.,finish grinding, grinding and polishing.

Machining precision:

1 After quenching,hardness of roller surface is HRC55~58

2 Roughness is Ra 0.01,finish14,temperature difference ≦±1℃,thermal deformation ≦0.01mm,straightness≦0.01mm

run out≦0.005mm, coaxiality≦0.005mm

Advantages:

High temperature control precision , good temperature uniformity, high heating and cooling speed, easy maintenance,

low energy consumption, safety, environmental protection, no pollution and so on.

Applications:

Used in plastic sheet, plate,film, paper, cloth, rubber, Anticounterfeiting laser materials,wash gold, textile,

printing and dyeing, metal,nonwovens, electronic and other industries for calendering ,Compositing, peritoneum,

drying, preheating, embossing,stripes forming etc.

Copyright @ 2013 Linjie Roller Factory all rights reserved ICP备案:浙ICP备10006466号

ADD:Fuerkang In,Heng he Industrial Zone,Feiyun Town,Rui'an City,Zhejiag,China Email:linjiezhigun@gmial.com TEL:0577-65010101 Fax:86-577-65026313