- Induction Heating Rolle

- Flexible copper clad la

- Mirror Roller

- Comma Scraper

- Coating Roller

- Heating Roller

- Chilling Roller

- Stainless Steel Roller

- Guide Roller

- Calender and Casting R

- Rubber Roller Series

- Anilox Roller

- Extinction Roller

- Telfon Roller

- Other Roller

PRODUCTS |

YOUR CURRENT LOCATION:HOME > PRODUCTS |

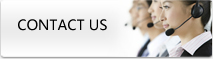

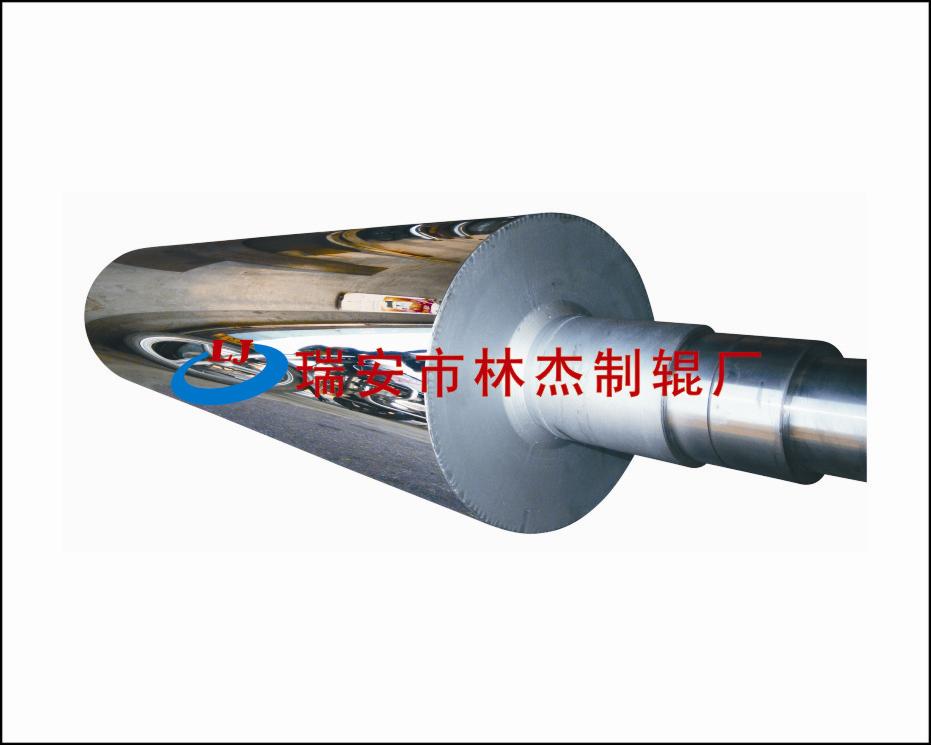

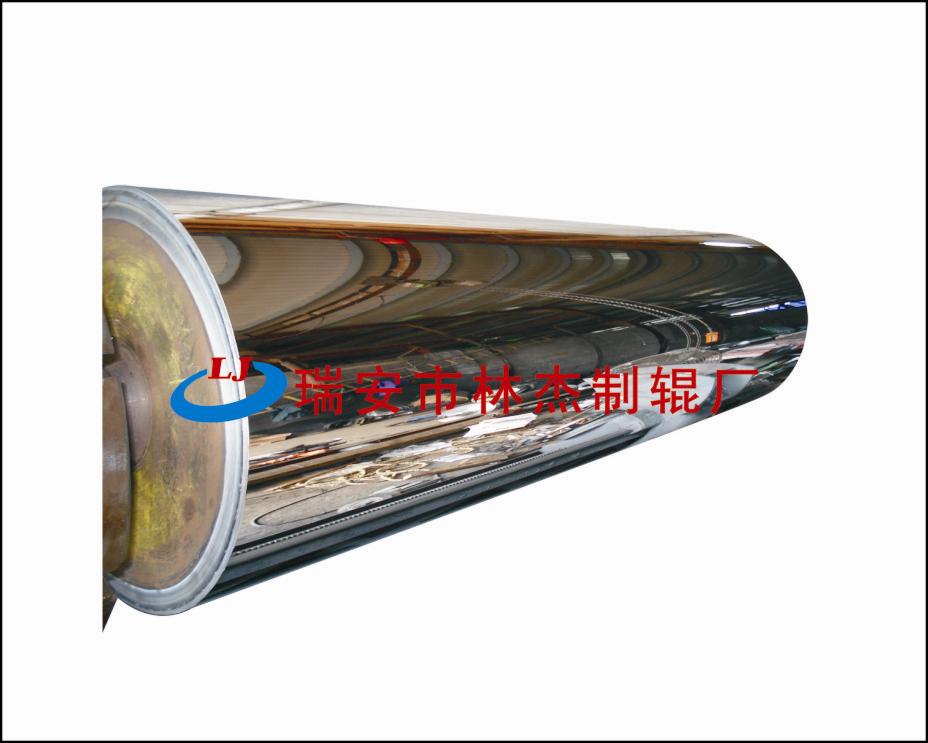

Heating Roller

Material :

high quality 45# steel tubes, alloy steel tubes, precision steel tubes, etc.

Processing: heat treating,finish turning ,welding ,destressing,quenching, accurate grinding,

hard chrome plating,

grinding and polishing by the 3M abrasive mirror polishing machine.

Parameter:

1.After quenching the,the hardness of the roller surface is HRC55~58,after hard chrome plating

it is above HRC65.

2. Roughness is Ra 0.01, finish14,straightness≦0.01mm , run out≦0.005mm, coaxiality≦0.005mm

Linjie Roller has lots of available heating ways .

Heating method:

1.Use conduction oil for heating

Install inner multispiral flow channel for brimming with conduction oil to heating or

install two-layer casing ,three- layer casing, Z type structure for heating by the oil.

(Heating temperature difference ≤±1℃ ,Thermal deformation ≤0.01mm. )

2. install electric heat pipes in the middle of the roller or around the roller’s body for heating

(Heating temperature difference ≤±1℃ ,Thermal deformation ≤0.01mm.

3.Use a heater for heating

Install an electric heat pipe in the middle of the roller or around the roller .

Use steam for heating

Let the hot steam in the roller for circulatory heating.

Application:

Used in plastic sheet, plate,film, paper, cloth, rubber, anti-laser Anti-counterfeiting laser materials,wash gold, textile, printing and dyeing, nonwovens, electronic or other

and topping with gum

Copyright @ 2013 Linjie Roller Factory all rights reserved ICP备案:浙ICP备10006466号

ADD:Fuerkang In,Heng he Industrial Zone,Feiyun Town,Rui'an City,Zhejiag,China Email:linjiezhigun@gmial.com TEL:0577-65010101 Fax:86-577-65026313